|

|

|

Equipment Safety

The 9900

is completely interlocked for maximum personnel and

equipment safety. All access panels, sputtering doors,

chamber pressure switches, and water flow switches are

interlocked to provide protection for personnel, the system

and the wafer load in process. |

|

|

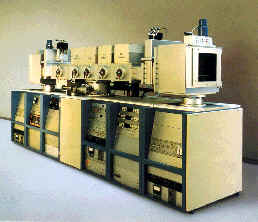

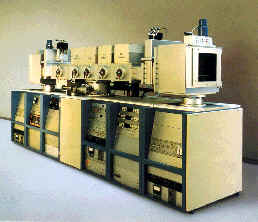

Typical 9900

(5) Target Sputtering System. |

Load

Lock

Up to 28 pallets can be loaded from either end of the

system. Once the pallets are loaded into an end chamber and

the load lock chamber has been evacuated to the preset

pressure, the load lock valves open to the process chambers

and the system is pumped down to a preset pressure before

deposition. |

|

CPA builds the

most reliable systems in the industry! In actual on-line

production use over the last seven years in some of the most

active and successful fabrication facilities in the world, CPA's

9900 Series operated at better than 90% up-time, including

normal shutdown for target replacement, chamber cleaning and

pump service. |

|

|

|

|

|