|

|

|

||||||||||||||

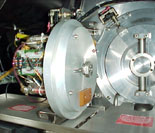

HIGH PERFORMANCE SPUTTERING SYSTEM The 3290 system sets the pace for state-of-the-art wafer sputtering. This new system is based upon the widely accepted and field-proven design of the acclaimed 3280. It provides significant improvements for even greater performance and reliability. |

|||||||||||||||

|

|

|||||||||||||||

Copyright 2003 - Control Process Apparatus, Inc. sales@sputteringneeds.com

Company | Systems | Parts | Services | Contact Us