|

|

|

|

|

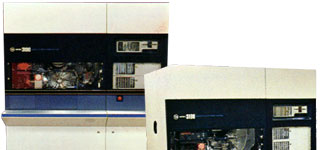

Fully Automated, Cassette to Cassette

Sputtering System offer

unexcelled Thin Film

processing

performance and field-proven reliability. |

|

Wafer handling and processing in

the 3180 systems are automated by 4 separate microprocessors.

Communication between the microprocessors allows the system to process wafers

in an efficient and user-friendly manner, with operator interaction provided

by a touch-panel CRT screen. The system prompts the operator when to load and

unload, and runs unattended between loadings. |

| 3180 system

configuration includes a substrate preheat module at Process Station 1.

For processes requiring precleaning of silicon wafer substrates for

"native oxide" removal, the preheat module can be replaced with an RF

Sputter Etch Module and its associated 1 kW Power Supply. |

|

|

|

|

The 3180 series of high

throughput, cassette-to-cassette sputtering systems has

become the industry standard due to superior performance and

field-proven reliability. Their unique design incorporating

individual wafer processing has been widely accepted and

proven in production lines throughout the world. |

|

|

|

|

The 3180 systems are designed so

that up to three sputtering sources can be provided, equipped

with either the same target material, or materials of

different composition for processes requiring sequential

deposition. Each system may also be equipped with an RF

Sputter Etch Module for in-situ substrate cleaning prior to

sputtering. Superior

Film Quality

High deposition rates of

approximately 12,000 A/min for aluminum alloys combined with

close coupling of the wafer to the Conical Magnetron (ConMag'm)

source provide films of unrivaled purity and morphology.

Potential sources of contamination are minimized since only

the wafer itself is loaded into the small volume load lock. |

|

Up to 28

pallets can be loaded at either end of a 9900 Series System.

Once pallets are loaded and the load-lock chamber is

evacuated, load-lock valves are opened and the system is

pumped down to a preset process vacuum. Pallets are

automatically lowered onto the transfer mechanism and moved

through the process chambers. The 9900 transport is

bi-directional so pallets can be transported back and forth

for sequential or multiple-pass deposition.

The 3180 offers automated

cassette-to-cassette processing, eliminating the need for

operator loading or handling of individual wafers. Each wafer

is automatically removed from the cassette, transferred into

the vacuum chamber through a load lock, indexed serially

through four process stations, and then returned to its

original slot in the cassette. |

|

|

|

|

|