|

|

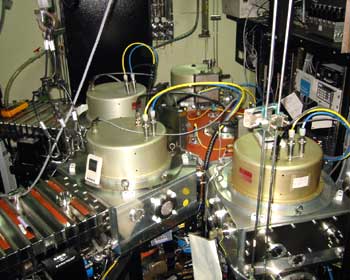

The CVC Connexion Cluster

Tool system is a modular system with stations for connecting up to six

modules around a central substrate-handling platform. Each module performs

a different manufacturing process on the substrate. The CONNEXION Cluster

Tool system enables the integration of modules supplied by either the

Company or third-parties. CPA currently offers a wide range of advanced

process modules for deposition and etching of thin film layers. |

|

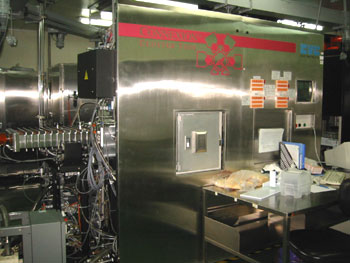

The CVC CONNEXION Cluster Tool

consists of a number of vacuum modules linked together through hardware

and software, allowing wafers to be transferred from module to module. |

|

The CONNEXION Cluster Tool, combined with a wide range

of process modules, helps to create highly uniform devices

through the integration of various processes in a vacuum

controlled environment. Its integrated, modular-based systems

provide functional flexibility that enables data storage and

semiconductor manufacturers to quickly transition to new

process technologies, improve time-to-market of higher

performance products and improve manufacturing yields |

|